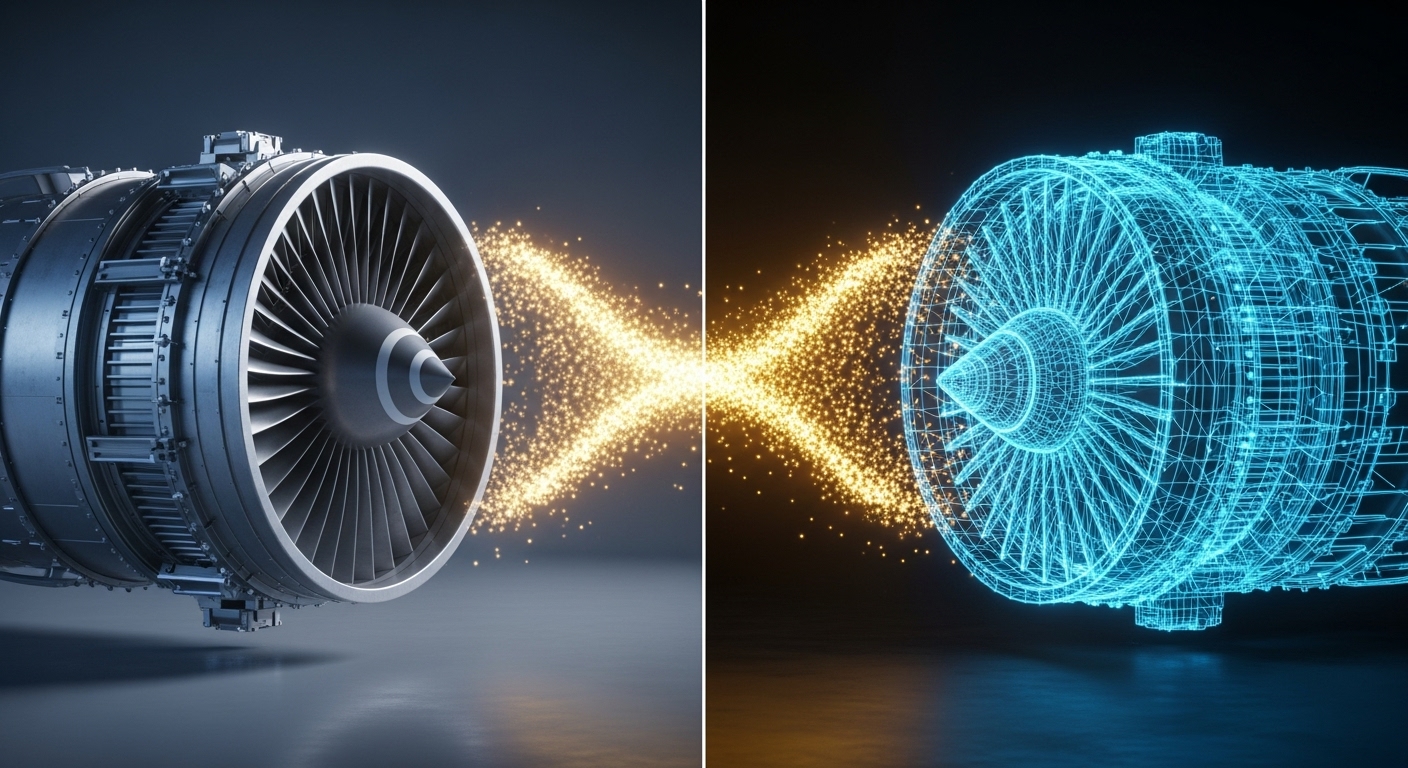

Digital Twin Lifecycle Management

Defining and ranking data fabrics and middleware to guarantee a single source of truth for assets over a 30-year lifecycle, from the design desk to field service.

Client

Global Heavy-Equipment OEM

Objective

Guarantee a Single Source of Truth

Timeline

10-Week Program

Key Focus

Data Integrity & Integration

The Challenge: Maintaining the Digital Thread

A digital twin delivers maximum value only when it stays in lock-step with the real asset across its entire lifecycle. Three major obstacles stall this "digital thread" and prevent universal rollout.

Data Integrity at Scale

Keeping BOM structures, sensor tags, and 3D meshes synchronized between disparate systems like CAD, PLM, and MES over 25+ years is a non-trivial data science challenge.

Heterogeneous Software Stacks

Firms juggle dozens of different enterprise software systems. Building and maintaining the "API glue" to connect them is costly and fragile.

Workforce Upskilling

Without targeted training and intuitive user interfaces, valuable insights from digital twins die in dashboards that legacy teams don't check or understand.

Key Outcomes: Five Lead Platforms for a Unified Lifecycle

Our analysis delivered a shortlist of five platforms that work together to create a seamless, end-to-end digital twin lifecycle.

Graph-Based Data Fabric

Auto-maps tags from PLM to MES to IIoT, ensuring <0.3% data drift after 5 years.

OPC UA + AAS Middleware

Provides 200+ ready connectors and a low-code UI for bridging legacy and modern systems.

Blockchain-Based Version Vault

Creates a tamper-proof audit trail for regulatory compliance and warranty claims.

Mixed-Reality Service Viewer

Overlays live sensor data on 3D CAD via HoloLens, boosting first-time-fix rates by 18%.

Adaptive Training Portal

Drives 82% monthly active user adoption with micro-learning and AR tutorials.

Strategic Impact: A Scalable Template

The OEM green-lit a 20-asset pilot using the graph-data fabric and mixed-reality viewer. The success of this pilot will set a scalable template for decades-long, continuously-synchronized digital twins—bridging design, production, and service while keeping data secure and teams empowered.